Feeding the IP with soft line or metal ends, with a soft line in between, should be fine. The leak at the IP end is probably from a bad seal inside the coupling. These seals are called ‘olives,’ and you can get them from an IH dealer or online. It’s important that seal is correct, or the system will leak diesel out and let air in. Air in the fuel lines to the IP or injectors is a huge problem for these IDIs. If there is air, the injectors won’t fire correctly.

If it were me, I’d remove the secondary filter setup. If the primary stock filter is doing its job, you don’t need another filter, and extra plumbing joints just give air a chance to get into the lines.

It looks like you don’t have a Shrader/bicycle valve on the system to bleed air out of the filter tower. You need a way to bleed air out. It should be in one of the outlet holes on the stock filter tower. Even if you add one back in, the second filter tower might still hold air due to the droopy line between the two. That’s another reason to ditch the second filter setup. Good luck.

@Oak

Good to know about the olives, I didn’t realize those existed. That might explain the intermittent clack too.

I think I’ll leave the second filter in just for an extra checkpoint for any chunks or nastiness when burning waste oil, mostly for peace of mind. The drain pipe on the side does the air bleeding job, plus there’s a starter button under the hood for that and setting the fueling on the IP.

The hard fuel lines are not really necessary and are outdated. A soft fuel feed line from the filter head to the IP is better. There are a few places that sell the components to do this. I removed both hard lines years ago and haven’t had any issues. And yes, you should get rid of that second filter header under the hood—it just clutters things up. For a while, I mounted a coolant filter off the fuel filter header, which I think is a better use of the space. And when you replace the valve cover gaskets, it’ll be easier without all the extra clutter from two filter headers.

@Wren

Actually, rocker torque check/retorque is on my list too. I’m getting that clack from one of maybe four things (rockers, valve, weak injector, or piston slap—all from the passenger rear corner) and it did sit for a while before I got it running again.

I’m thinking of leaving the second filter as I may as well filter and burn my used oil. It’s all just diesel, so why not? Won’t hurt, and it’s not much of an obstacle when you grew up around British Leyland machines.

Good to know. I haven’t had any problems so far, and soft lines give some flexibility. The hard line one guy cut up had too little pressure to back the soft lines off properly.

@Reeve

It’s a long shot, but I had a weird sound from the passenger side, and it turned out to be a failed starter gear bouncing off the flywheel, making a racket. A few damaged teeth, but no issues 50k miles later.

@Wren

That could be it too. The clutch and flywheel are falling apart on this one.

Reeve said:

@Wren

That could be it too. The clutch and flywheel are falling apart on this one.

Check for play/looseness by removing the inspection cover. It should be pretty obvious. I went with a LUK single mass flywheel and clutch kit, no problems since.

@Wren

What inspection cover? ![]()

It’s still tight, just have a jingling throwout bearing and a broken spring on the pressure plate.

Which setup did you go with? My 7.3 is mated to the original T19.

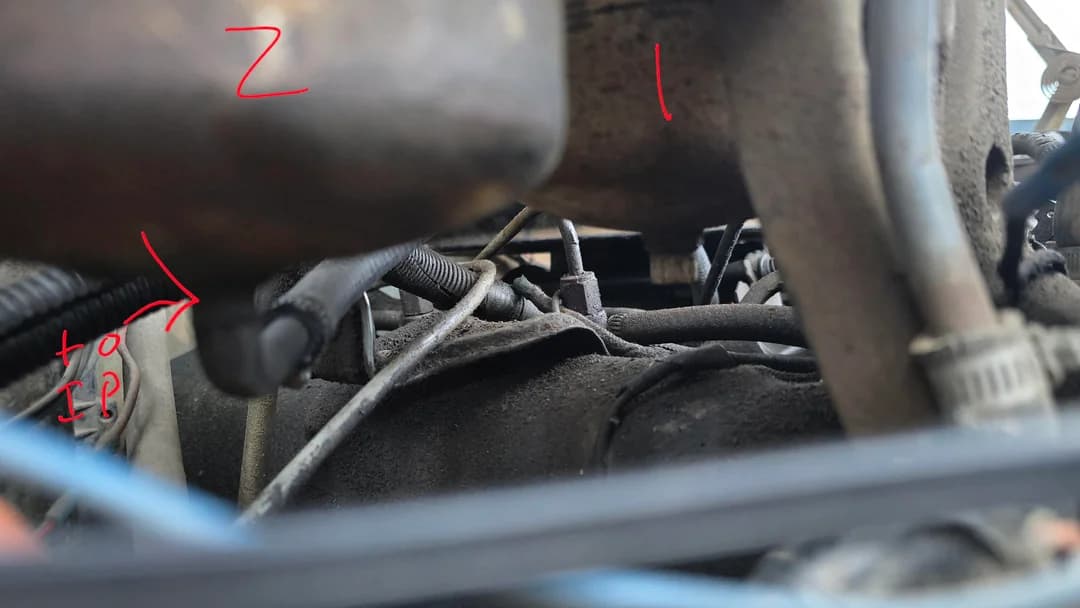

That looks like an old 6.9 style filter next to a 7.3 style filter.

Stevie said:

That looks like an old 6.9 style filter next to a 7.3 style filter.

I was wondering if that was the case. It’s an '88 block 7.3 with some 6.9 parts on it. I’m guessing it was swapped in the late '90s when the 6.9 went out.

@Reeve

Well, the 7.3 filter is better because it has a water separator in it. But it looks like the water sensor is blocked off.

Stevie said:

@Reeve

Well, the 7.3 filter is better because it has a water separator in it. But it looks like the water sensor is blocked off.

It is. Whoever put it together just got it running and called it good. I run treatment every so often though—it helps with biodiesel poisoning and clears out any water. CA is so dry I don’t really have a problem with condensation. The inside of the tanks are almost rust-free.

@Reeve

If you can avoid biodiesel, I would suggest you do, because it can polymerize inside your fuel system and ruin everything if the truck sits for even a couple of months.

Stevie said:

@Reeve

If you can avoid biodiesel, I would suggest you do, because it can polymerize inside your fuel system and ruin everything if the truck sits for even a couple of months.

I try my best. The northern half of the state uses mostly bio. If I can get my rear tank working again, I’ll have 50+ gallons and bio won’t be a problem.